Unlocking Business Success Through Advanced Bulk Material Handling Solutions

In today’s rapidly evolving industrial landscape, the efficiency of material movement plays a pivotal role in determining the overall productivity, safety, and profitability of various businesses. Particularly within sectors such as electronics and 3D printing, precise and reliable bulk material handling systems are no longer optional—they are essential. Implementing state-of-the-art solutions not only streamlines operations but also provides a significant competitive edge in an increasingly demanding global marketplace.

Understanding the Importance of Bulk Material Handling in Modern Business

Bulk material handling refers to the process of transporting, storing, controlling, and protecting large quantities of raw materials, intermediate products, or finished goods. The core objective is to facilitate the smooth and efficient flow of materials while minimizing operational costs, reducing waste, and ensuring safety.

In sectors like electronics manufacturing and 3D printing, managing various raw materials—such as powders, filaments, resins, or small electronic components—is crucial for maintaining product quality and operational efficiency. Effective bulk material handling solutions enable businesses to optimize workflow, reduce downtime, and maintain high standards of precision, which ultimately leads to enhanced customer satisfaction and increased profitability.

The Role of Bulk Material Handling Systems in Enhancing Business Efficiency

Implementing sophisticated bulk material handling systems impacts various facets of business operations:

- Increased Processing Speed: Streamlined material flow reduces bottlenecks, allowing for quicker production cycles.

- Enhanced Safety: Proper handling systems minimize workplace accidents related to material spillage, falling objects, or manual handling injuries.

- Cost Savings: Reduced labor costs, minimized material waste, and optimized storage contribute to overall financial efficiency.

- Better Quality Control: Precise material delivery and controlled environments ensure consistency in manufacturing processes.

- Scalability: Modular and adaptable handling systems allow for expansion as business demands grow.

Innovative Technologies Driving Bulk Material Handling Forward

Recent advancements have revolutionized how industries approach bulk material handling, incorporating cutting-edge technologies that boost effectiveness and reliability:

Automated Conveyors and Robotic Systems

Automated conveyor systems equipped with sensors and PLC controls ensure seamless movement of materials with minimal human intervention. Robotics further enhance handling precision, particularly useful for delicate electronic components or high-value 3D printing materials.

Smart Storage Solutions

Intelligent storage systems utilizing RFID and barcode scanning facilitate real-time inventory tracking and management. These solutions reduce errors, streamline replenishment, and ensure consistent material supply.

Bulk Material Dispensers and Feeders

Advanced feeders provide constant and controlled flow of powders, resins, or small components, critical for maintaining quality in electronics manufacturing and additive manufacturing (3D printing).

Integrated Data and Control Systems

IoT-enabled systems gather data from various handling units, providing comprehensive insights into operational efficiency, predictive maintenance needs, and safety compliance. Real-time analytics enable proactive decision-making, minimizing downtime.

Specialized Bulk Material Handling Solutions for Electronics Industry

The electronics sector demands precision and cleanliness in handling sensitive materials like microchips, electronic components, and rare earth elements. Customized bulk material handling systems address these needs through:

- Cleanroom-Compatible Conveyors: Ensures contamination-free transport in sterile environments.

- Vibratory Feeders: Enable precise feeding of electronic components with minimal damage.

- Dust Control and Filtration: Protect sensitive electronics from airborne particles during handling.

- Modular Storage Modules: Facilitate organized storage of components, enabling quick access and inventory management.

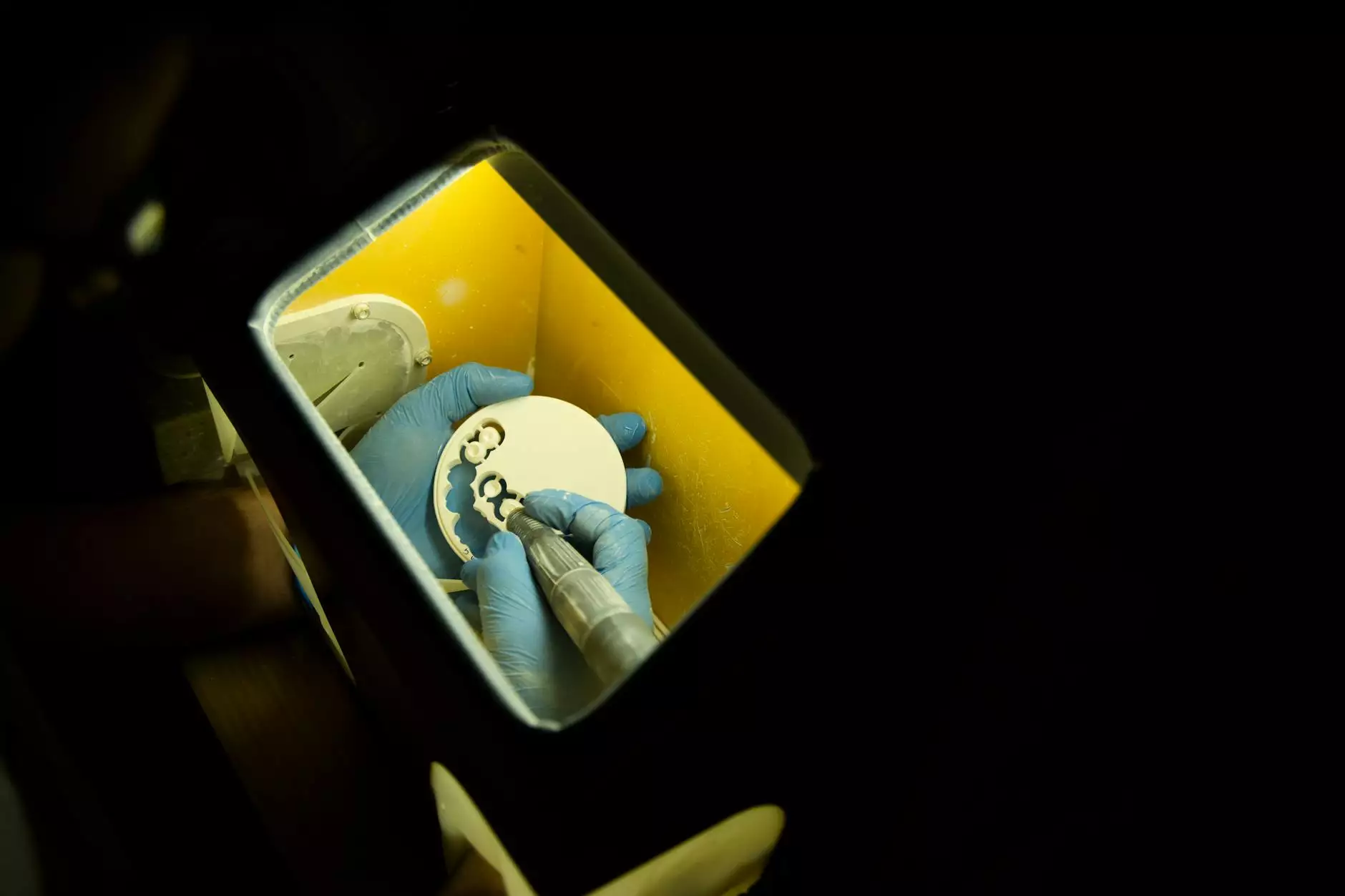

Enhancing 3D Printing Efficiency with Superior Bulk Material Handling

The 3D printing industry heavily relies on the effective management of powders, resins, and filament materials. Key aspects include:

- Powder Handling Systems: Utilize vacuum and gravity-based equipment to transfer powders safely and accurately into printers, ensuring material consistency.

- Resin Management: Incorporate closed-loop dispensers that reduce waste and prevent contamination.

- Filament Storage and Feeding: Deploy climate-controlled storage along with automated feeders for continuous operation.

- Safety and Waste Management: Systems designed to contain fine powders and chemical vapors, protecting operators and the environment.

Choosing the Right Bulk Material Handling Solutions for Your Business

Selecting the optimal system requires a detailed understanding of your operational needs, material types, and future growth plans. Considerations include:

- Material Characteristics: Particle size, flowability, chemical properties, and sensitivity influence system design.

- Operational Scale: Volume throughput, storage capacity, and space availability determine the scale of handling solutions.

- Environmental Conditions: Temperature, humidity, and cleanliness requirements shape system specifications.

- Automation Level: Degree of automation needed for workflow efficiency and labor optimization.

- Safety Protocols: Regulatory compliance, hazard prevention, and user safety measures must be integrated into system design.

Benefits of Partnering with Specialized Bulk Material Handling Providers

Partnering with experienced providers like PolygonMach ensures access to:

- Customized Solutions: Tailored systems designed to meet specific industry requirements.

- Cutting-Edge Technology: Access to the latest innovations in automation, control, and safety features.

- Comprehensive Support: From initial consultation and installation to maintenance and upgrades.

- Industry Expertise: Deep knowledge of electronics and 3D printing operations enables strategic design choices.

- Cost-Effective Investment: Optimized systems that reduce long-term operational costs and maximize ROI.

Future Trends in Bulk Material Handling

The future of bulk material handling lies in increased automation, smarter systems, and sustainable practices:

Integration of Artificial Intelligence (AI)

AI-driven systems will enable predictive analytics, autonomous operation, and adaptive control, further enhancing efficiency and safety.

Environmental Sustainability

Development of eco-friendly materials, energy-efficient machinery, and waste reduction technologies are becoming paramount, aligning industrial practices with environmental goals.

Enhanced Data Analytics

Big data will inform better decision-making, maintenance scheduling, and process optimization, creating more resilient and flexible handling systems.

Conclusion: Transforming Business Operations with Next-Generation Bulk Material Handling

In conclusion, effective bulk material handling systems are a cornerstone of modern business excellence, especially within the electronics and 3D printing industries. They drive efficiency, improve safety, and support scalability, laying a solid foundation for growth. Embracing innovative technologies and partnering with expert providers like PolygonMach can propel your business to new heights, ensuring you stay competitive in today’s fast-paced industrial environment.

Investing in advanced bulk material handling solutions is not just about optimizing operations—it’s about pioneering your industry’s future and achieving excellence through smart, reliable, and sustainable practices.