Revolutionizing Efficiency: The Rise of the Automatic Painting Machine

The automotive sector is experiencing a significant transformation, driven by technological advancements and increasing demands for quality and efficiency. Among these innovations, the automatic painting machine stands out as a game-changer. This sophisticated equipment not only streamlines manufacturing processes but also ensures superior paint application, reducing waste and improving the overall quality of automotive finishes. In this comprehensive article, we delve into the world of automatic painting machines, their benefits, applications, and the future of painting technology in the automotive industry.

What is an Automatic Painting Machine?

An automatic painting machine is an advanced piece of equipment designed to apply paint uniformly and efficiently on various surfaces, primarily in industrial settings such as automotive manufacturing plants. These machines utilize advanced technology, including robotics and automated systems, to control the painting process with precision. They significantly reduce the need for manual labor, lower the incidence of human error, and enhance the consistency of paint application.

Key Benefits of Using Automatic Painting Machines

The adoption of automatic painting machines in the automotive industry offers numerous advantages. Here are some of the most significant benefits:

- Enhanced Efficiency: Automatic painting machines streamline the painting process, ensuring faster turnaround times and higher production rates. Businesses can produce more vehicles in less time, thereby meeting increasing market demands.

- Improved Quality: These machines provide consistent and even paint application, minimizing defects such as runs, sags, and uneven coating. This leads to a higher quality finish that enhances the aesthetic appeal of vehicles.

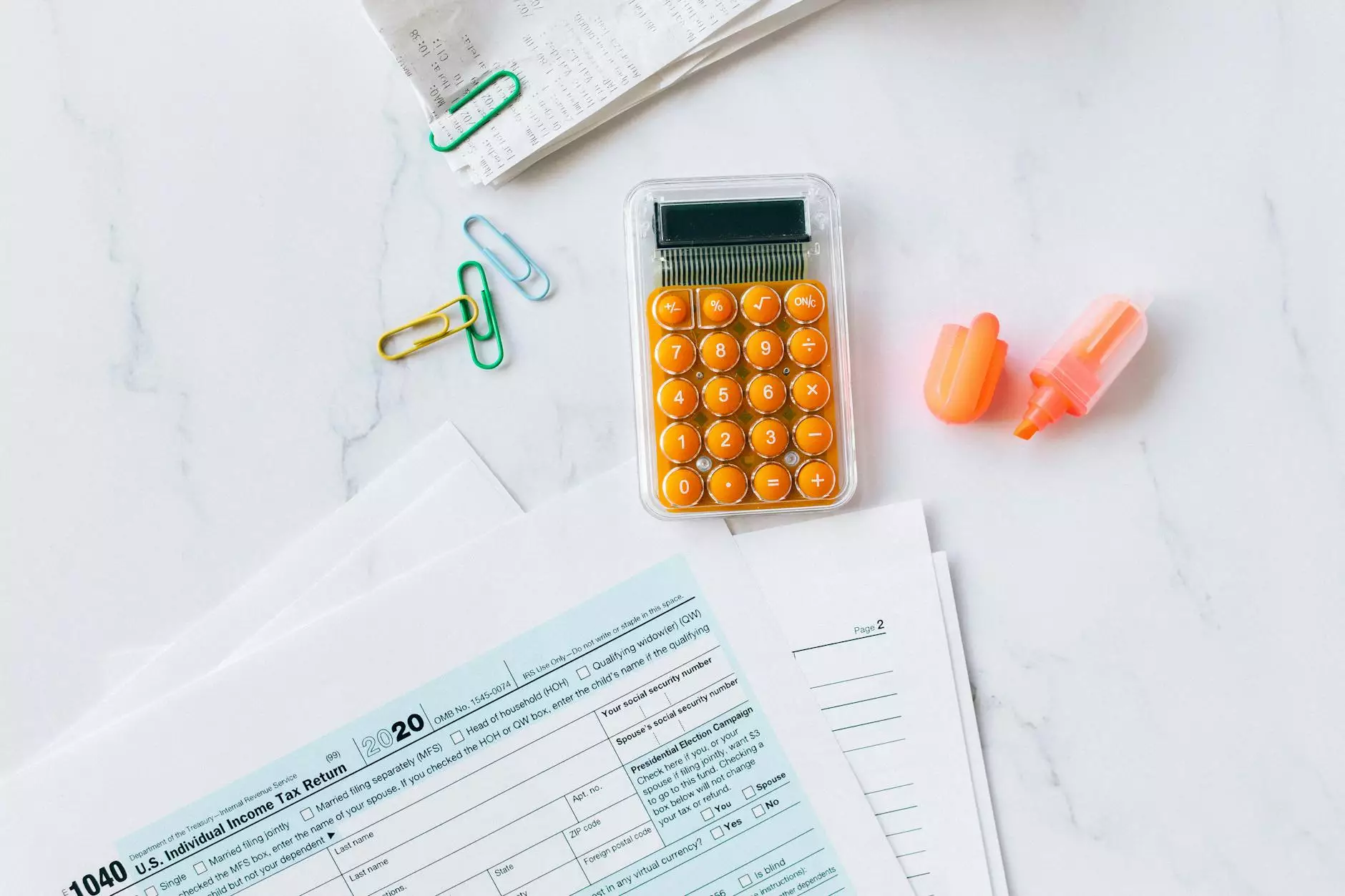

- Cost-Effectiveness: While the initial investment in automatic painting technology may be high, the long-term savings are substantial. Reduced labor costs, decreased paint consumption due to precise application, and less waste contribute to overall cost reductions.

- Environmentally Friendly: Automatic painting machines are designed to minimize overspray and waste, making them more environmentally friendly compared to traditional methods. They can also utilize water-based paints, further reducing harmful emissions.

- Flexibility and Adaptability: Modern automatic painting machines can be programmed and adjusted to handle various painting requirements, including different types of finishes and colors, enabling manufacturers to respond quickly to market trends.

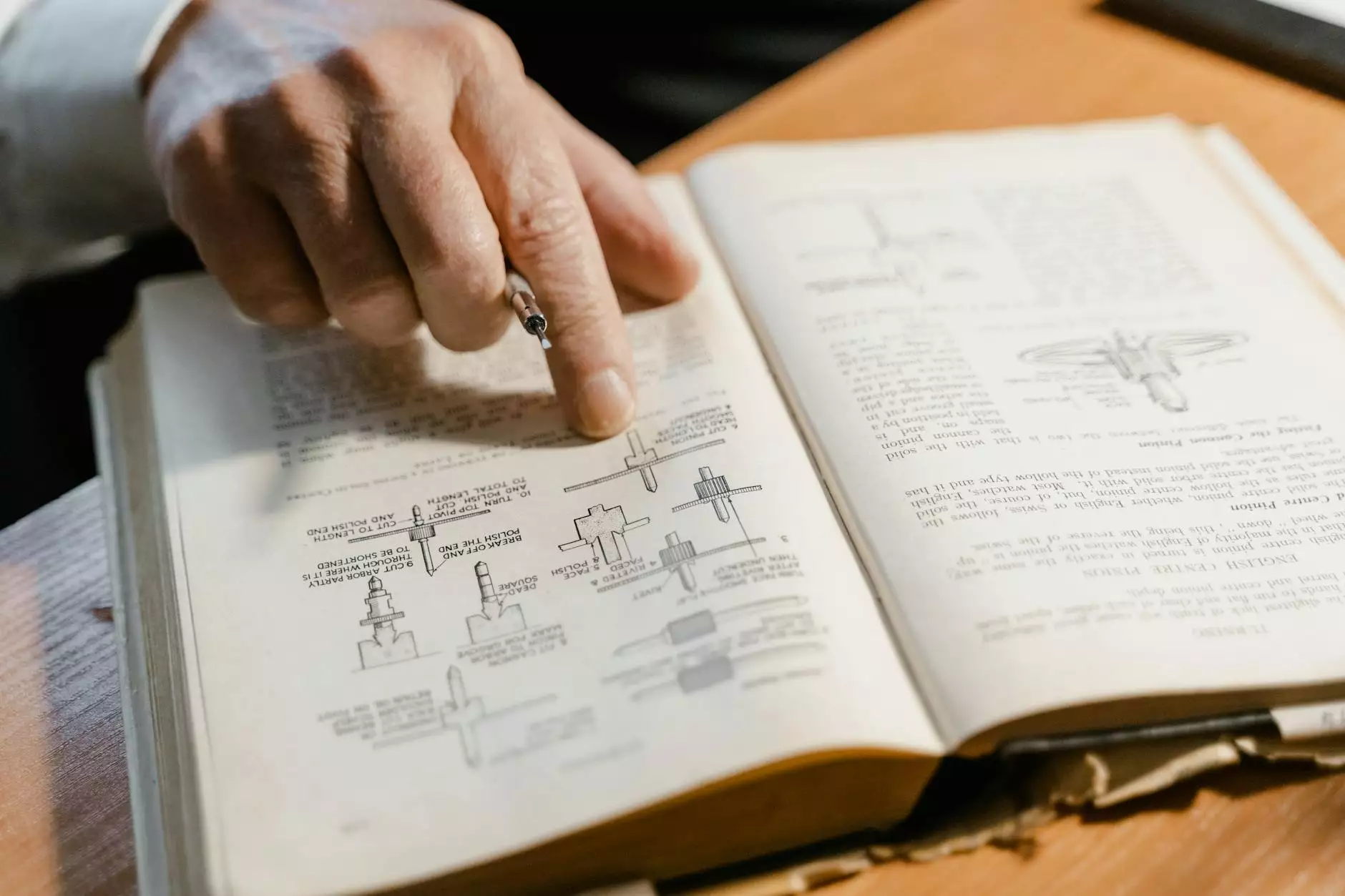

Understanding the Technology Behind Automatic Painting Machines

To fully appreciate the impact of automatic painting machines, it’s essential to understand the technology that powers them. Here are key components that make these machines effective:

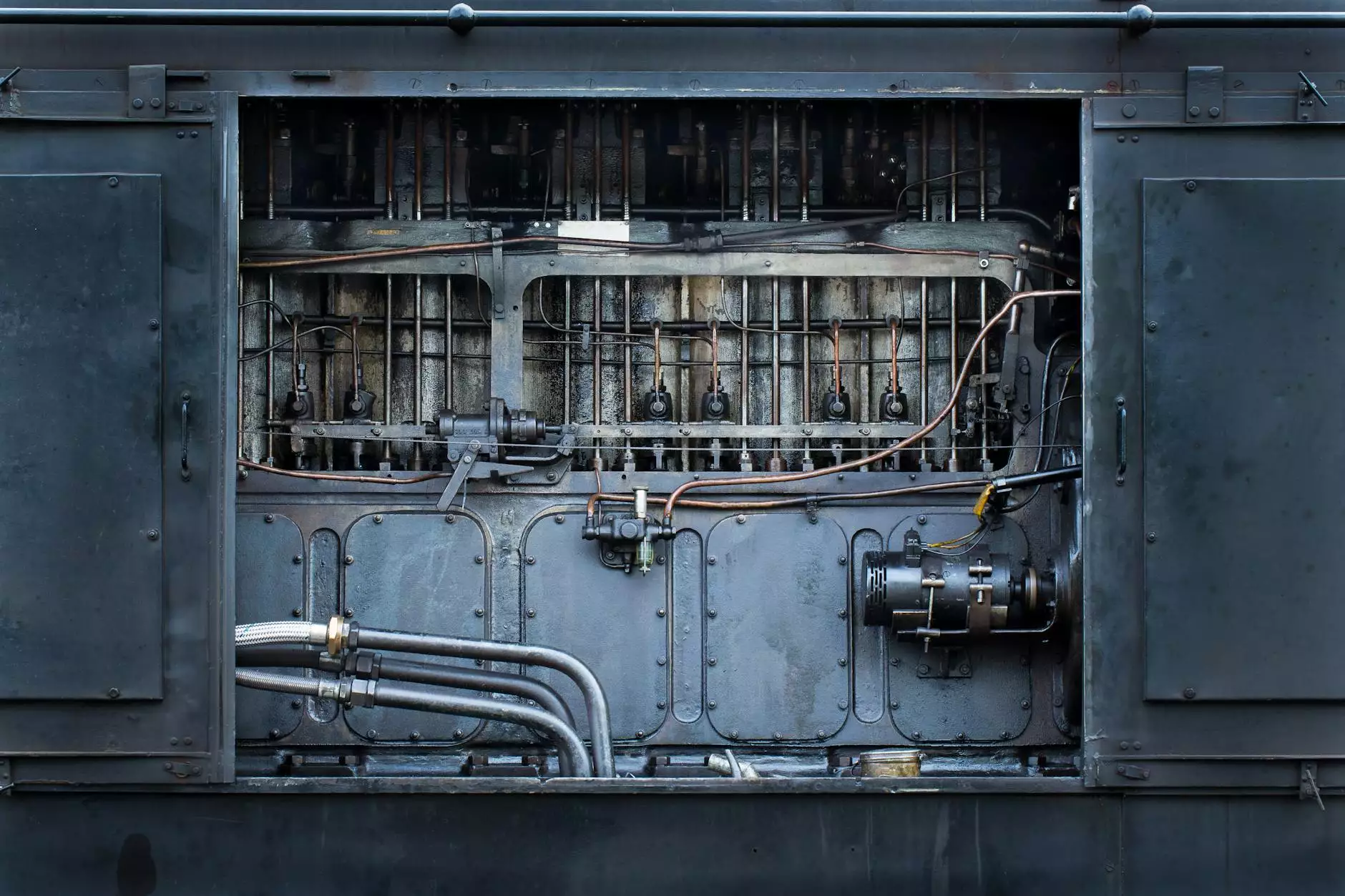

1. Robotics and Automation

Robots are integral to the operation of automatic painting machines. These robots are equipped with precise movements and control systems that allow them to apply paint consistently. The automation of painting processes reduces the variability associated with human painters, resulting in a more uniform coating.

2. Advanced Sensors

Automatic painting machines utilize advanced sensors that monitor the painting process in real-time. These sensors ensure optimal paint thickness and coverage, alerting operators to any inconsistencies that may arise during the painting process.

3. Computerized Control Systems

The integration of computerized control systems allows for easy programming and adjustments. These systems can also track production metrics and facilitate quality control, ensuring that each painted surface meets the required standards.

4. Efficient Paint Delivery Systems

Modern machines feature advanced paint delivery systems that optimize paint usage and minimize waste. For instance, pressure-fed systems and recirculation methods allow for precise control over the paint that is dispensed, ensuring that no paint is left unused.

Applications of Automatic Painting Machines in the Automotive Industry

Automatic painting machines are utilized across various stages of automotive manufacturing. Here are some primary applications:

1. Vehicle Body Painting

The most common application is in the painting of vehicle bodies. Automatic machines ensure an even application of primer and paint on the entire surface, leading to better corrosion resistance and improved aesthetics.

2. Component Painting

In addition to complete vehicles, these machines can also paint smaller components such as grilles, spoilers, and trim pieces. This ensures that every element of the vehicle maintains a consistent look and quality.

3. Touch-Up and Repair Painting

Automatic painting machines are increasingly used for touch-up jobs and repairs. Their precision allows for targeted application, making it easier to blend repairs with the existing finish.

4. Custom Paint Jobs

With the ability to program various designs and finishes, automatic painting machines can produce customized paint jobs that meet specific consumer preferences, expanding the opportunities for automobile manufacturers to cater to niche markets.

The Future of Automatic Painting Technology

The future of automatic painting machines in the automotive industry looks promising. As technology continues to evolve, several trends are emerging:

- Increased Customization: With the rising demand for personalization among consumers, manufacturers are expected to invest more in automatic machines that can handle complex designs and color variations.

- Integration with Industry 4.0: The digital revolution in manufacturing, known as Industry 4.0, is influencing the development of automatic painting machines. Enhanced connectivity will lead to better data collection and analysis, driving improvements in the painting process.

- Sustainability Focus: As environmental concerns grow, manufacturers are likely to emphasize sustainable practices, encouraging further innovations in automatic painting technology to reduce waste and emissions.

- Smart Machines: The incorporation of artificial intelligence and machine learning will enable automatic painting machines to adapt and improve their processes autonomously, making them more efficient over time.

Conclusion: Embracing Innovation in Automotive Painting

The automotive industry is rapidly adopting advancements like the automatic painting machine to enhance productivity and meet the evolving needs of consumers. By embracing this technology, manufacturers can ensure consistent high-quality finishes while promoting sustainability and efficiency.

As the landscape of automotive manufacturing continues to change, businesses that invest in automatic painting solutions will be well-positioned to lead the market. With lower costs, improved quality, and reduced environmental impact, the future of painting technology is bright, and automatic painting machines are at the forefront of this transformation.

For more insights about automatic painting machines and how they can benefit your automotive business, visit AutoCoat India.